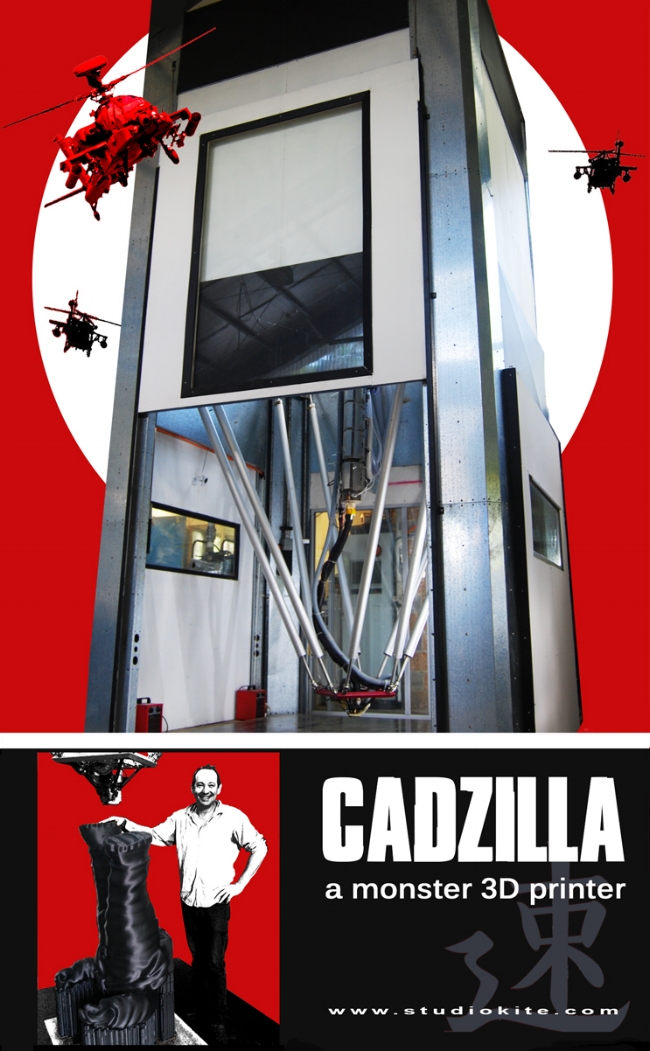

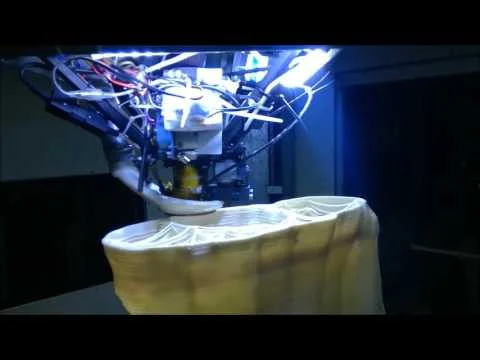

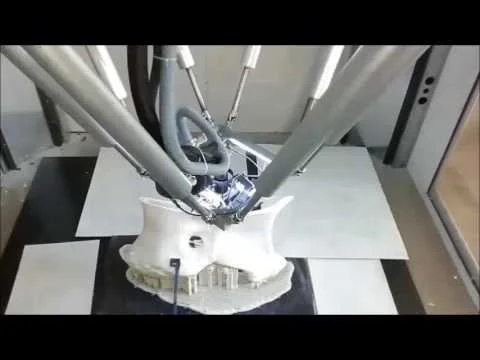

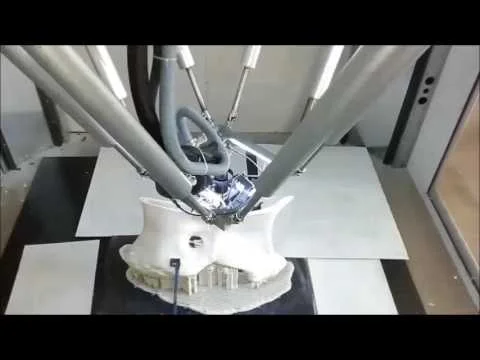

We are excited to introduce CADzilla. Brain child of director, Steve Rosewell, who designed and fabricated this monster of a 3D printer. It has revolutionised the way we build sets and props at Studio Kite. Not only will we realise your props and sets with this 3D printer, it will be on the market soon so you can have your very own.

Some technical specs follow:

Build chamber in configurations up to 2.6m x 2.6m by 3.6m.

Printing speeds up to 24m/min

Layer heights .4 to 6mm

Raw chipped material can be printed at up to 25kg per hour.

Heated chamber up to 80°c to prevent warping

Materials include ABS, PE, PP, PLA, PVC and more.

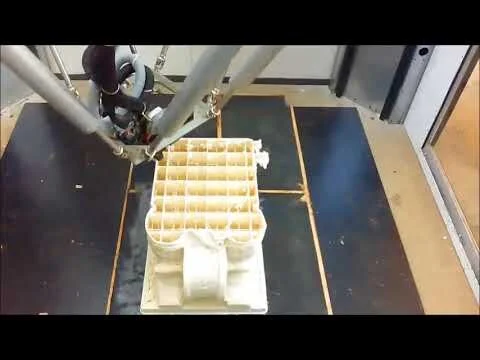

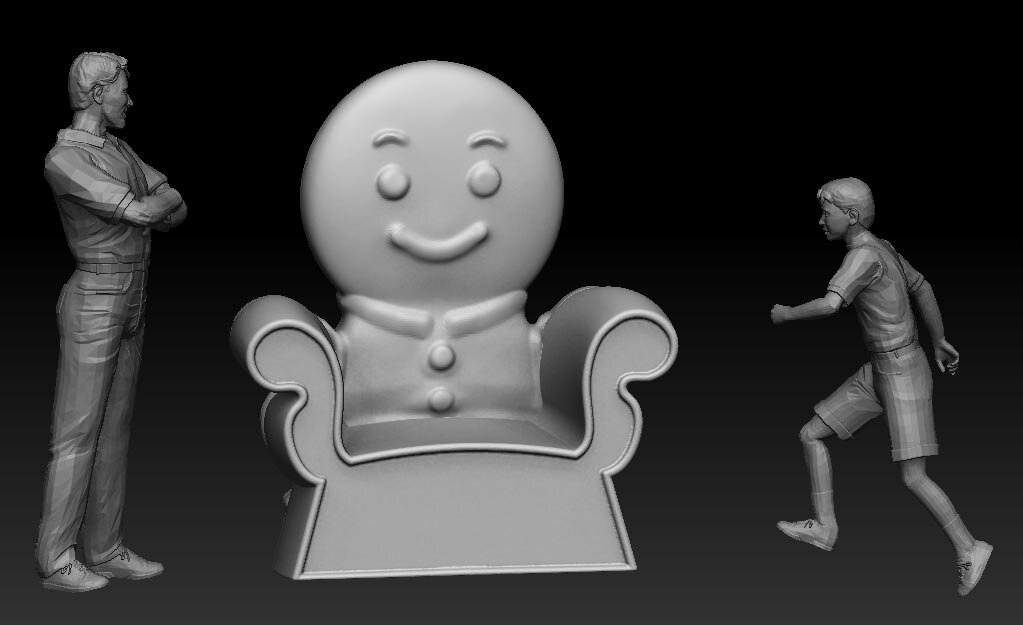

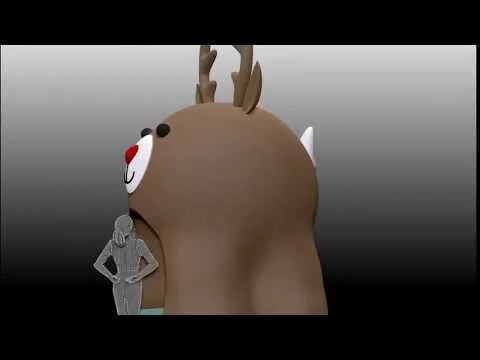

Producing large shelled objects commonly involved CNC machining blocks of foam, then applying a urethane hard coat or fiberglass. 3d printing on this scale produces strong durable objects quickly with minimal material, waste and labour costs. Parts can be finished with a water based acrylic modified cement material which is weather proof and tough. Also, epoxy, polyester filler or acrylic spray putty will bond to the printed material. Glass fibre can be added to the plastic to reduce shrinkage and improve stiffness. This is especially helpful if high quality gloss paint finishes are required. Studio Kite can print your provided 3d model or we can design to your specifications whether it be an engineering component or sculptural art installation. All 3d printed objects can be fully recycled and this recycled material can be reprinted. 3d printing is overall less toxic and produces far less waste making it a far better choice for the environment.